INDUSTRIAL & MANUFACTURING

INDUSTRIAL & MANUFACTURING OVERVIEW

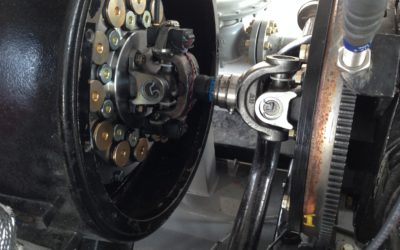

TorqueTrak systems are used in a variety of industrial & manufacturing settings to diagnose problems, increase throughput, and reduce downtime. Whether a steel plant or a paper plant, you can be sure that Binsfeld products are robust enough to handle some of the most extreme environments.

INDUSTRIAL & MANUFACTURING CASE STUDIES

Torsional Vibration Measurements on Reciprocating Compressor

THE CLIENTStructural Dynalysis was founded in 2002 and specializes in structural dynamics, vibration testing & analysis, signal processing and driveline dynamics. In addition to the testing services provided, Structural Dynalysis provides thorough torsional...

Pump Efficiency Testing With Torque Telemetry

THE CLIENTIntegrity Pump & Motor specializes in the design, manufacturing, and testing of a wide variety of pumps used across numerous industries. Integrity-built pumps have been used at golf courses, mines, agriculture, municipalities, and countless other...

High/Low Torque Alarm on Vertical Roll Mill in Cement Plant

THE CLIENTFounded in 1996, Torkflex has established itself as a leading provider of products and engineering services in mechanical drives. Headquartered in Ribeirão Preto city, São Paulo,, Brazil Torkflex has serviced over 100 customers in the South America region in...

Axial Thrust Measurement in Vertical Turbine Pump

Engineering Dynamics Incorporated (EDI) was requested to help perform an axial load test on a vertical water pump. Since commissioning, the pump experienced accelerated bearing and shaft wear. There was concern that problems might be due to up-thrust resulting in a...

Monitoring Cooling Conveyor Torque

Engineers at a chocolate factory in Chicago, Illinois had an expensive problem with one of their cooling conveyors. Trays loaded with hot confections were moved through a series of air cooling tunnels by the conveyor. Each tunnel section had an independent length of...

Troubleshooting Overloads at Hot Strip Mill

Bethlehem Steel, Sparrows Point, MD - Plant engineers had deduced that sporadic torque overloads on a rolling stand in the hot strip mill were causing breakdowns of the expensive drive system. What the engineers didn't know was why. Was it a function of the width or...

Increasing Process Throughput Of Paper Machine

International Paper Company - Plant personnel were not able to run the year-old paper machine at full speed. Either the two drive motors were not producing the rated horsepower or the process required more horsepower than the drives could produce. Motor current...

Diagnosing Rolling Mill Performance Problem

IPSCO Steel, Axis, Alabama - A rolling stand at IPSCO Steel consistently under-performed - it was unable to reduce six-inch thick slabs by the 1.25 inches desired. Engineers suspected the drive motors might be the cause. Before making this claim to the motor...

Measuring Actual Torque on Automotive Stamping Press

Nissan Motors, Smyrna, TN - Repetitive breakdowns of the transfer drive (moves parts through) on a stamping press were restricting production. The press manufacturer said the machine was designed for 18 strokes per minute but running it faster than 10 spm caused drive...