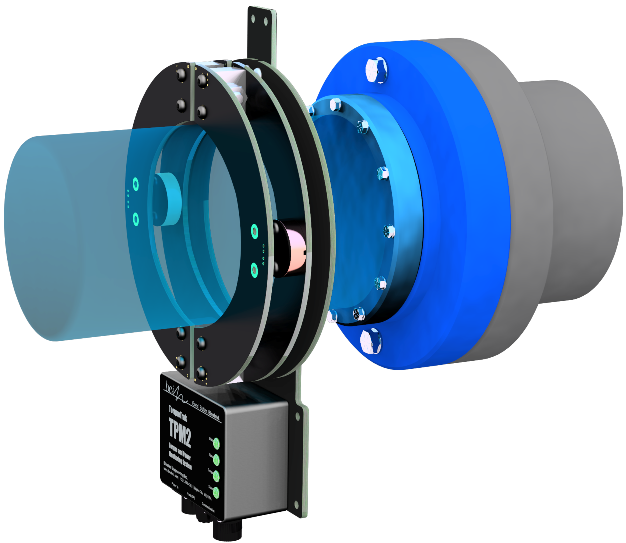

TORQUETRAK TPM2

TORQUE & POWER MONITORING SYSTEM

The TorqueTrak Torque and Power Monitoring System (TPM2 series) is a rugged precision instrument designed to measure torque and/or power on rotating shafts in real time using precise strain-gage sensors. The TPM2 is custom designed to fit on shafting as low as .75″ (19mm) and up to 48″ (1220 mm) in diameter. Machine disassembly is not required.

- .1% Instrumentation Accuracy

- Multiple Outputs Available

- RS485 Modbus RTU

- Analog (+/- 5V, 0-5V, +/ -10V, 0-10V) (with Analog Output Module)

- RS422 High-Frequency Protocol

- One-Time Calibration (No re-calibration required)

- Durable – IP67 rated, Vibration Tested to MIL-STD-167-1A, Shock Tested to MIL-STD-810H

- High RPM / centrifugal g-force rating (For example 6900 RPM at 191mm/7.5″ )

- Fits Small Shafts

- 91mm/3.6″ minimum shaft space

- 19mm/.75″ minimum shaft diameter

DOCUMENTATION

TT TPM2 User Guide [PDF]

TT TPM2 Modbus User Guide [PDF]

TT TPM2 Analog Output User Guide [PDF]

TT TPM2 Datasheet [PDF]

TT TPM2 Software Manual [PDF]

TT TPM2 Installation Kit [PDF]

FAQ

DATA ACQUISITION

TorqueTrak Sensor Interface (TTSI)

TORQUE CALCULATORS

Range Calculator >

Torque Strain Calculator >

MARKETS

Marine >

Mining >

Industrial & Manufacturing >

Energy >

Agricultural >

Civil Engineering >

FEATURES & BENEFITS

Easy Installation – Rotating Collar and Stationary Ring are split and bolt together around the shaft. No Machine assembly or Shaft modification is required.

Robust Construction – Sturdy hardware and electronics, built for demanding environments.

Reliable Operation – Inductive power and data transfer with generous clearance between stationary and rotating parts. No wear surfaces.

System Status Indicators – Confirm proper operation at a glance. Expedites troubleshooting.

Easy-on Collar – Rotating Collar is designed to accommodate small variations in shaft diameter and clamps to the shaft using standard tools.

Communications Made Easy – High-speed bi-directional communications link interfaces with PC or PLC. User-selectable sample rate up to 4800 samples/second.

Product Support – Backed by BEI’s proven outstanding customer service, before and after the sale.

POWER SUPPLY INPUT:

10 – 30 VDC @ 10 W (nom), 15 W (max)

TORQUE SENSOR

TORQUE SENSOR INPUT:

Strain gage bridge, 350 ohms (std), 120 ohms (min)

Input Range: user-selectable from 0.025 to 32 mV/V

Shunt Calibration: 2 user-selectable: 1 mV/V and 0.2 mV/V (350 ohm bridge)

TORQUE SENSOR RESOLUTION:

15 bit (32,768 points)

TORQUE SIGNALS

Output |

Baud Range |

Sampling Rate |

Bandwidth |

Signal Delay |

| RS422 | 1200 to 460.8K* | 9.375 to 4800 Samples/Second* | 3 to 1000 Hz | 1 to 1700 msec** |

| RS485 (Modbus RTU) | 9600 to 460.8K* | Max~240 Samples/Second*** | Max~ 80 Hz*** | 1 to 1700 msec** |

|

Analog (+/- 5V, 0-5V, +/ -10V, 0-10V) |

460.8K (fixed) | 9.375 to 4800 Samples/Second* | 3 to 1000 Hz* | 1.8 to 1860 msec** |

*User-configurable

**Dependent on sampling rate

***Dependent on Modbus baud and polling rate

GENERAL

SHAFT SPEED AND DIRECTION:

Measured once per revolution

Resolution:1 5 bit (32,768 points), auto-ranging

ACCURACY:

Zero error: ±0.1% FS (max), Scale error: ±0.2% (max)

OPERATING ENVIRONMENT:

-40° to +70° non-condensing

Specifications are subject to change without notice.