TORQUE & POWER

MEASUREMENT MADE EASY.

Most rotary torque measurement solutions are inaccurate, require extensive driveline modification, or are prohibitively expensive. It shouldn’t be that way. Having started in the field ourselves, we understand the challenges you face, which is why we developed easy-to-use torque telemetry instrumentation that will give you the measurements you need quickly and accurately. All of this means you can spend less time worrying about measurements and more time focusing on what matters most.

Measurements you need in

8 hours or less by

following 3 simple steps:

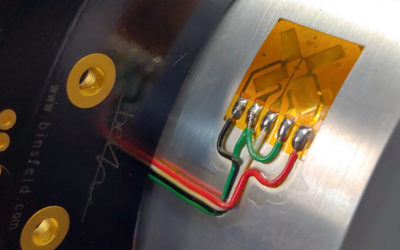

1) Install a Strain Gauge

It’s Easy! See our Shaft Strain Gaging Guide

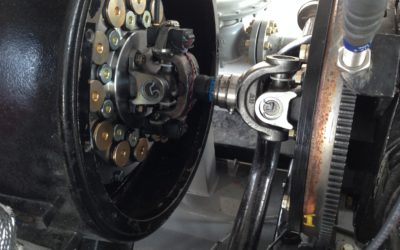

2) Attach Binsfeld Telemetry

Simple – see our training videos

3) Acquire Data

Use your own DAQ or ours.

Our Solutions

TEMPORARY TORQUE MEASUREMENT

PERMANENT TORQUE & POWER MONITORING

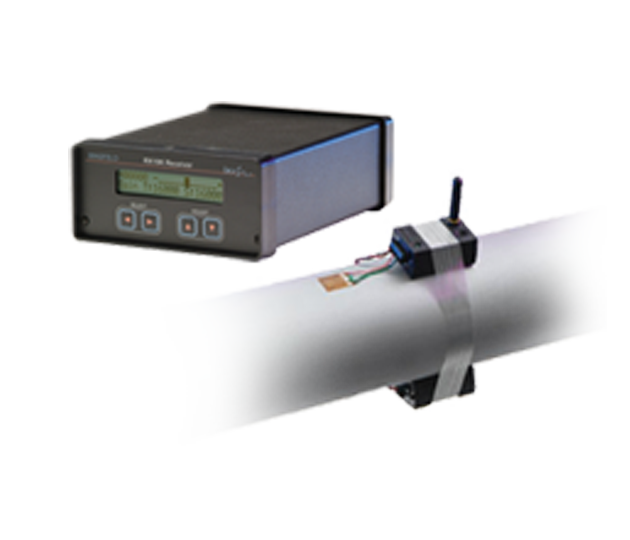

TORQUETRAK 10K

Temporary torque measurement system for rotating shafts

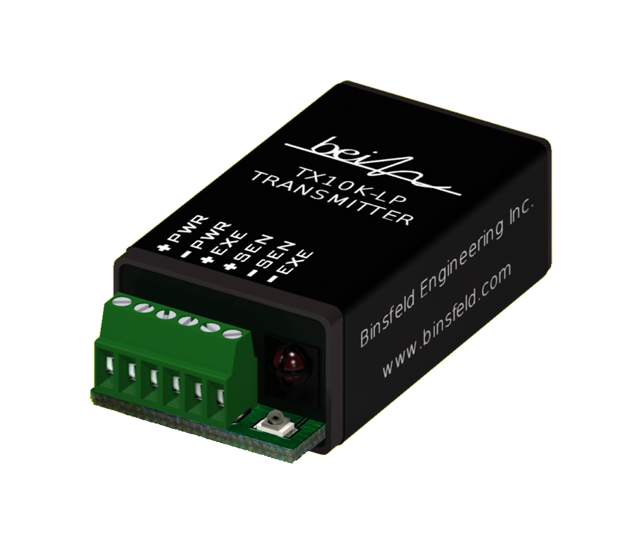

TORQUETRAK 10K-LP

Low-profile temporary torque measurement system for rotating shafts.

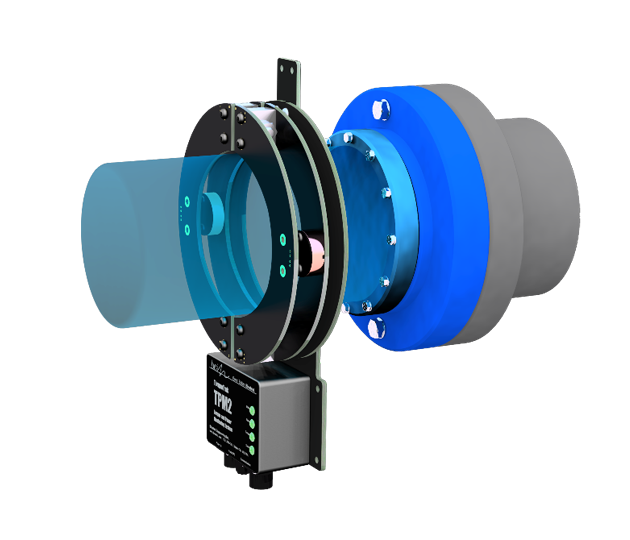

TORQUETRAK TPM2

Sealed torque and power monitoring system with digital data output.

Our Clients

Technical Topics

What is a Strain Gage (Gauge) and How Does It Work?

Strain gages (sometimes referred to as strain gauges) are exceptionally useful measurement tools, often because of their sensitivity. As evidence, strain gages are typically used as the sensing elements in precision load cells, the most precise "load" measurement...

How Torque Telemetry Works

What is torque telemetry? Torque telemetry is a wireless method of measuring torque on a rotating shaft. At its most fundamental level, a torque telemetry system's "job" is to energize, transmit, and process the data received from a sensor (such as a strain gage,...

How to Measure Torque on an Existing Shaft

When it comes to measuring torque on a rotating shaft, there are several options available depending on the application. The most common and well-known rotary torque measurement systems are in-line torque transducers. As the name suggests, these transducers are...

Case Studies

Torsional Vibration Measurements on Reciprocating Compressor

THE CLIENTStructural Dynalysis was founded in 2002 and specializes in structural dynamics, vibration testing & analysis, signal processing and driveline dynamics. In addition to the testing services provided, Structural Dynalysis provides thorough torsional...

Harbor Towing Optimization

BACKGROUND With increased emissions regulations and rising fuel costs, vessel owners are constantly looking for ways to reduce fuel consumption of their fleet and tugboats are no exception. In a typical tug operation, there are 2 basic modes of operation: in-transit...

Pump Efficiency Testing With Torque Telemetry

THE CLIENTIntegrity Pump & Motor specializes in the design, manufacturing, and testing of a wide variety of pumps used across numerous industries. Integrity-built pumps have been used at golf courses, mines, agriculture, municipalities, and countless other...

Subscribe to our newsletter!

BINSFELD ENGINEERING INC.

4571 W. MacFarlane Rd.

Maple City, MI 49664 USA

TORQUETRAK

Binsfeld’s Torque Measurement Systems measure true mechanical torque and power on rotating shafts. We also offer consultation, strain gaging and installation services.

TEMPTRAK

Binsfeld’s Rotary Temperature Transmitter Systems provide accurate and reliable temperature control on heated godets and calendars. We also offer design and OEM services.

TORQUETALK NEWSLETTER

Sign-up to receive featured application stories, relevant news, tips, and new product release information for our torque measurement products.