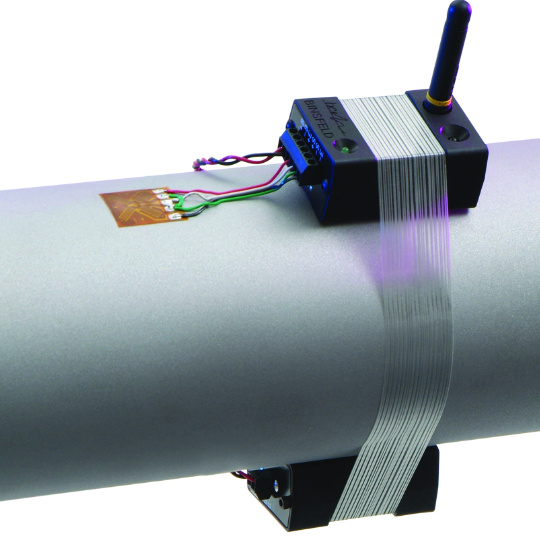

TORQUETRAK 10K

WIRELESS TORQUE SENSOR FOR ROTARY TORQUE MEASUREMENT

Measuring live torque in real-time is easier than ever with the TorqueTrak 10K telemetry system. Convert virtually any drive shaft into a rotating torque sensor by simply mounting the wireless torque transmitter, battery and a torque-sensitive strain gage to the shaft. Use the infrared remote control to adjust transmitter gain, activate the remote shunt calibration or switch the transmitter to standby power mode. The multi-line LCD receiver display and keypad make system adjustments straightforward. Low power consumption in the rugged transmitter allows longer battery life while sophisticated electronics assure accurate and reliable torque data output.

DOCUMENTATION

TT10K User Guide [PDF]

TT10K Datasheet [PDF]

TX10K-S Transmitter Drawing [PDF]

BH10K Battery Holder Drawing [PDF]

RX10K Receiver Drawing [PDF]

RM10K Remote Control Drawing [PDF]

FAQ

DATA ACQUISITION

DAQ10K Datasheet [PDF]

OpDAQ Field Test 2 Manual [PDF]

TORQUE CALCULATORS

Range Calculator >

Torque Strain Calculator >

MARKETS

Marine >

Mining >

Automotive >

Industrial & Manufacturing >

Energy >

Agricultural >

Civil Engineering >

FEATURES & BENEFITS

Easy to Use – Fits any size shaft, any torque level. No machine modifications or disassembly required. Calibration is done off-the-shaft. Receiver display and keypad offer user-friendly interface.

Infrared Remote Control – Control transmitter operation including channel select, gain/range, shunt calibration and low-power standby mode.

Reliable Data Transmission – Clean, noise-free data signal through analog voltage output or digital data output via RS-232.

Standby Power Mode – Extends transmitter battery life without disconnecting the battery.

16 Channels, – 500 Hz Frequency Response Use multiple systems simultaneously.

Rugged – Reinforced, injection-molded transmitter housing is built for demanding applications and features V-groove and tape slot for secure mounting.

User Adjustable Gain – Amplify the strain/torque signal to the most useful level.

TX10K-S STRAIN TRANSMITTER

SENSOR INPUT:

Full (four-arm) Wheatstone Bridge strain gage (350Ω standard)

BRIDGE INPUT:

2.5 VDC, ±0.1%

SENSOR RANGE:

User selectable per chart below (chart based on gage factor = 2.0):

| TRANSMITTER GAIN | FULL BRIDGE 4 ACTIVE ARMS (TORQUE OR BENDING) |

FULL BRIDGE 2.6 ACTIVE ARMS (TENSION OR COMPRESSION) |

1/4 BRIDGE 1 ACTIVE ARM (SINGLE GAGE) |

| 16000 | ±125 MICROSTRAIN | ±192 MICROSTRAIN | ±500 MICROSTRAIN |

| 8000 | ±250 MICROSTRAIN | ±385 MICROSTRAIN | ±1000 MICROSTRAIN |

| 4000 | ±500 MICROSTRAIN | ±769 MICROSTRAIN | ±2000 MICROSTRAIN |

| 2000 | ±1000 MICROSTRAIN | ±1538 MICROSTRAIN | ±4000 MICROSTRAIN |

| 1000 | ±2000 MICROSTRAIN | ±3077 MICROSTRAIN | ±8000 MICROSTRAIN |

| 500 | ±4000 MICROSTRAIN | ±6154 MICROSTRAIN | ±16,000 MICROSTRAIN |

SENSOR & POWER CONNECTION:

Screw terminal block

TRANSMITTER POWER INPUT:

7.0 to 18VDC (9V battery typical)

TRANSMITTER POWER CURRENT:

Transmit Mode: 40 mA nom, 50 mA max with 350Ω bridge

Standby Mode: 4 mA nom, 5 mA max

TRANSMITTER BATTERY LIFE:

24 hours in Transmit Mode (9V lithium, 350Ω bridge, 25°C)

TRANSMISSION FREQUENCY:

903-925 MHz

TRANSMIT DISTANCE:

20 feet or more

G-FORCE RATING:

3000 g’s (steady state) (e.g. 6500 rpm on a 5 inch diameter shaft)

OPERATING TEMPERATURE:

-30° – 85°C(-22° – 185°F)

SIZE AND WEIGHT (WITHOUT ANTENNA):

1.00″x 1.63″x 2.50″, 3 oz (25 mm x 41 mm x 64 mm, 85 grams)

RM10K REMOTE CONTROL

For use with TX10K-S Strain Transmitter

CONTROL FUNCTIONS:

Channel select; Gain/Range; Shunt Calibration 1 and 2; Power Standby

TRANSMIT TYPE AND DISTANCE:

Infrared; up to 10 feet (for use when transmitter is not rotating)

RX10K RECEIVER

VOLTAGE OUTPUT:

±10 VDC, field adjustable 0.25x to 4.0x

5-way binding posts (banana jacks)

DIGITAL OUTPUT CONNECTION:

RS232 type DB9 connector (cable provided for PC COM port)

RECEIVER POWER INPUT:

12VDC nominal (10 – 18VDC acceptable), 300 mA max

(110VAC or 220VAC adapter provided)

OPERATING TEMPERATURE:

-20° to 70°C (-4° to 158°F)

SIZE AND WEIGHT:

2.88″ x 5.75″ x 8.50″, 2 lbs (73 mm x 146 mm x 216 mm, 1 kg)

TT10K SYSTEMS

RESOLUTION:

14 bits

GAIN ERROR1:

±0.25%Reading (max), 25°C ambient

GAIN TEMPERATURE COEFFICIENT1:

±0.005%Reading/°C (max), 0 – 50°C ambient

OFFSET ERROR1:

±0.16%FS (max), 25°C ambient

OFFSET TEMPERATURE COEFFICIENT1:

±0.004%FS/°C (max), 0 – 50°C ambient

FREQUENCY RESPONSE2:

0 – 500 Hz (-3dB @ 500Hz)

DELAY2:

4.2 msec, typical

SAMPLE TRANSMISSION RATE:

2400 samples/sec

1TX10K Gain = 4000

2RX10K filter setting = 500Hz

One of the best tools for taking torsional measurements in the field has been the Binsfeld TorqueTrak 10K. It is easy to install and provides a clean signal torque. We have used it to successfully troubleshoot torsional failures of many systems such as VFD motors, reciprocating compressors, couplings, etc. We have also used the TorqueTrak 10K to measure axial thrust in vertical pump systems. In fact, we like the TorqueTrak 10K so much that EDI currently owns six of them!

TROY FEESE

SENIOR FIELD ENGINEER

ENGINEERING DYNAMICS INC