Harbor Towing Optimization

BACKGROUND

In a typical tug operation, there are 2 basic modes of operation: in-transit and ship assist. The only valuable work is during the ship assisting. Transit is an unfortunate necessity.

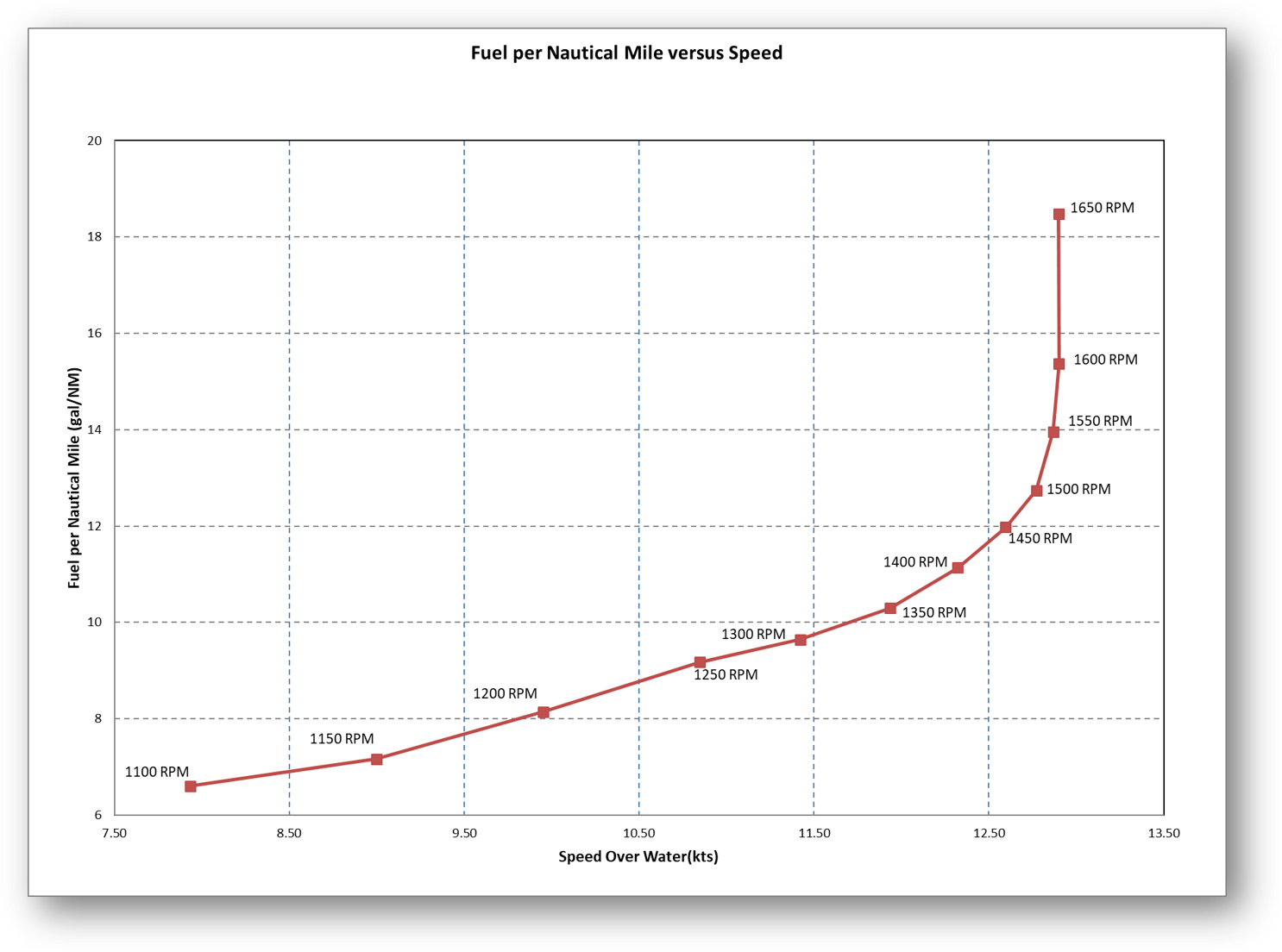

Tugboats are not designed to be efficient at high speeds. The figure below shows that there is a point where an increase in RPM results in marginal gains in speed over water, while fuel consumption increases considerably. When in transit between the dock and the vessel to be assisted, there is no advantage for the tugboat to sail at high speed but they are often operated too fast, leading to a higher fuel consumption than is necessary. Some shipowners try to set speed limits, but without monitoring it is unsuccessful. Operating crews reduce their speed but after a couple weeks, old habits come back and they are back to the starting point. To monitor effectively, it is critical to measure the fuel consumption in transit. This is where the Binsfeld Vessel Performance Monitoring system comes in – allowing for seamless measurement of the most important parameters.

A tug company in Canada decided to use a performance monitoring system to determine whether implementing the technology would provide an adaquate ROI and help them reduce operating costs.

THE SOLUTION

The Shaft Power Meter provided accurate horsepower data and the Flow Meters provided accurate fuel consumption data. They were used over standard engine readings due to their higher accuracy, which provided more opportunity for efficiency gains.

The Op-HMI uses an innovative algorithm to detect whether the tug is in transit or assisting another boat. The system also integrates the signals from the shaft power and fuel sensors to provide the operational status of the tug to the captain. The data helped instruct the captain to respect the speed limits while in transit. The innovative algorithm detects the operational state with great reliability without the captain having to enter data manually.

The Op-Fleet Online Dashboard allowed administrators to see the consumption statistics of the tug and to see if the limits were respected. This dashboard was also used to provide the operating crew with real-time feedback on how well they were doing.

THE IMPACT

The system was trialed on the tug over a period of a year, and provided the data needed to make significant financial impacts to the ship’s operations.

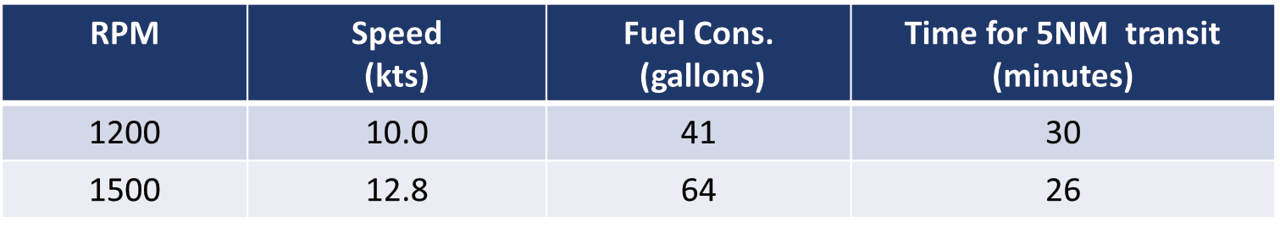

By monitoring vessel speed, fuel consumption, engine RPM, and operational mode, the shipowner was able to determine that a decrease in just 2.8 knots during the daily 5NM transit would save 23 gallons per day, while only delaying transit time by 4 minutes. Additional reductions in speed allowed the crew to eventually increase this to 31 gallons per day totaling a savings of 11,315 gallons per year (~$30,000).

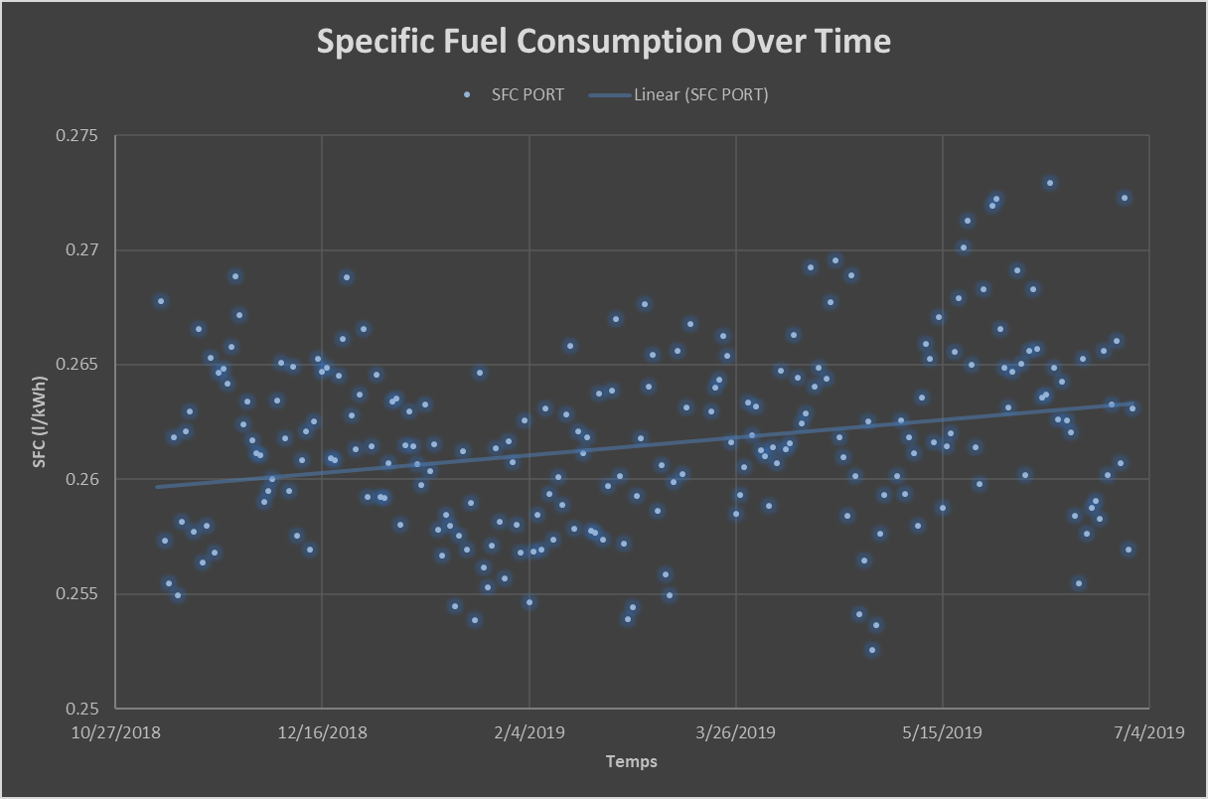

Maintenance managers were also able to monitor the engine performance and help delay maintenance intervals. By monitoring specific fuel oil consumption with fuel and shaft power meters, the engine performance trend was determined and used to determine when the engine is will be in need of an overhaul. The maintenance teams expects to delay major engine overhauls by 50% (from every 12,000 to every 18,000 hours).

By implementing the vessel performance monitoring system, the shipowner was able to significantly reduce operating costs for this vessel and stands poised to implement this across their entire fleet. By reducing fuel costs, the technology has enabled them to receive a fast ROI and a competitive advantage over other tug operators.