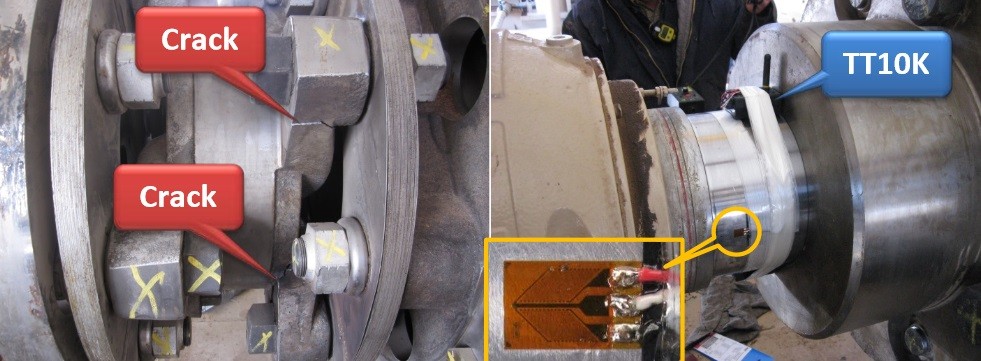

Weeks after commissioning, a compressor unit tripped on high motor vibration. Upon inspection, cracks were found in the center piece of the coupling indicating a possible torsional vibration problem.

The unit consisted of a 3150 HP induction motor operating at 894 RPM, shim pack coupling, flywheel, and 4-throw reciprocating compressor. Full load torque (FLT) of the motor was 222,000 in-lb. After the coupling was repaired, a Binsfeld TorqueTrak TT10K system and a Micro-Measurements strain gage were installed on the motor shaft to measure both transmitted (average) torque and dynamic (alternating) torque.

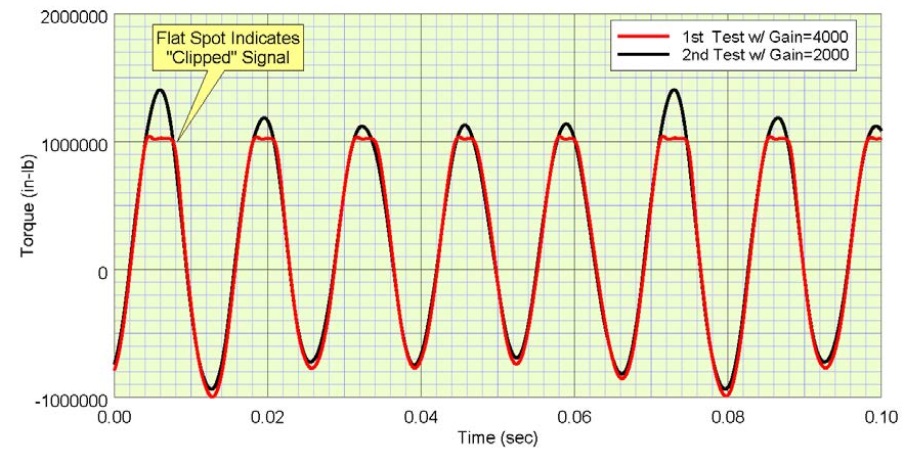

Peak torque of more than 450% of FLT was initially found with the compressor loaded, which is considered excessive even for reciprocating machinery. However, the signal appeared clipped so the unit was shut down to adjust the transmitter. It is important to check the time wave forms for flat spots, spikes, drop – outs, etc. to ensure good data collection.

Binsfeld includes a convenient remote control that allows easy changing of settings such as channel and gain. Without any soldering of pads, the remote was used to quickly switch the gain from 4000 to 2000. The unit was re-started and the maximum torque was actually 630% of FLT (1,400,000 / 222,000= 6.3).

One engineer questioned the calibration since the torque readings were extremely high. Further comparison with other measurements such as motor current and cylinder pressures verified correct horsepower and that the Binsfeld system was accurate. In addition, the remote had been used to perform built-in shunt calibration during installation of the TT10K to check for proper scale factor.

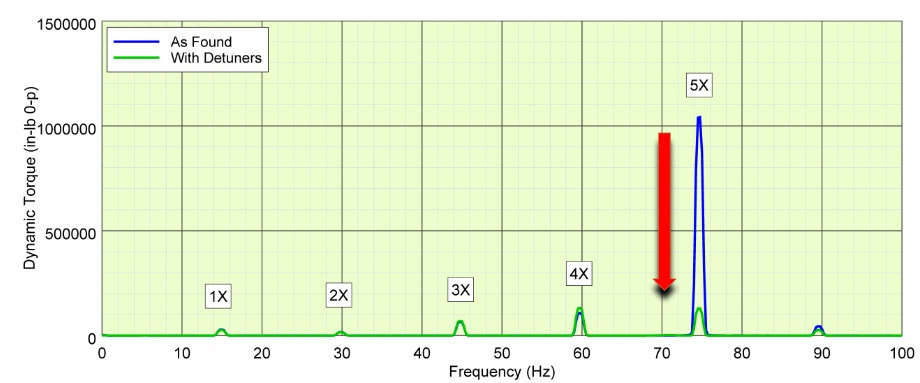

The high torque exceeded the coupling manufacturer’s allowable limits and caused the failure. The first torsional natural frequency (TNF) was coincident with 5× running speed, which greatly amplified the dynamic torque (AF ˜ 80). For a reliable system, the TNF should have a separation margin (SM) from significant compressor harmonics. API recommends a SM of 10% if possible.

The compressor manufacturer offers “detuners” or internal flywheels that can be bolted onto the crankshaft. This compressor frame can accommodate three detuners, which were promptly ordered from the factory and express shipped to the site. Within a few days the modified compressor unit was re-tested. Strain gage measurements confirmed that this additional inertia lowered the first TNF from 75 Hz to 71 Hz (now 5% below 5× running speed) thus reducing the torque amplitude at that harmonic. The torque levels are now considered acceptable.

By Troy Feese, P.E. Engineering Dynamics Incorporated – San Antonio, Texas, USA http://www.engdyn.com/