LamaLo Technology Inc. (LLT) commonly conducts marine propulsion shafting vibration and powering measurements in support of new construction, propulsion upgrades, and troubleshooting. Binsfeld TorqueTrak 10K telemetry systems are used to measure the shaft torque. Measurements are displayed in near-real time on the lap top computer, so an assessment of the vibration severity and delivered shaft power on-site.

A recent project involved a vessel that was built in 1969. The propulsion system had two fixed pitch propellers, each driven by a diesel engine. The vessel had gone under various refits since construction, including adding sponson tanks in 1976 and new diesel engines in 1980. In 2010/2011, the vessel had a refit conducted, which included upgrades to the shafting and propeller, and the addition of a bulbous bow and a bow thruster. The vessel service speed was 11.5 knots prior to the upgrade.

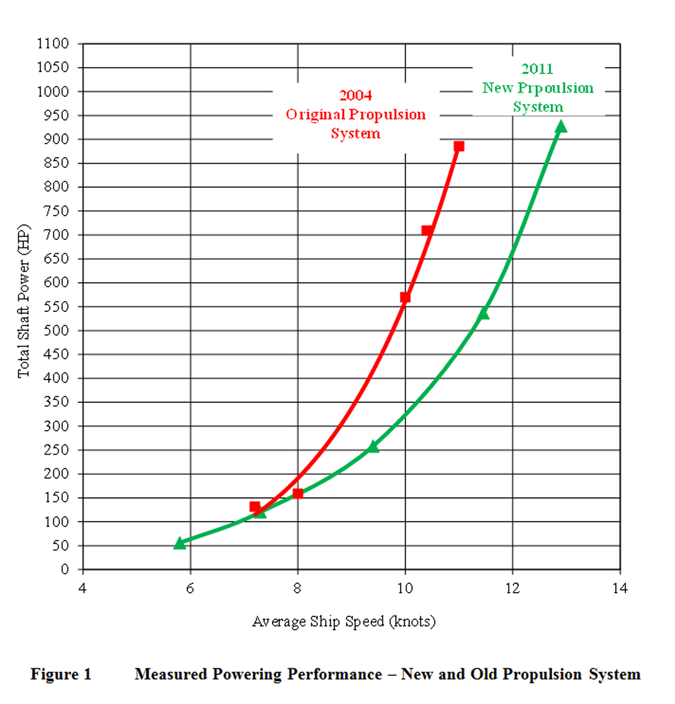

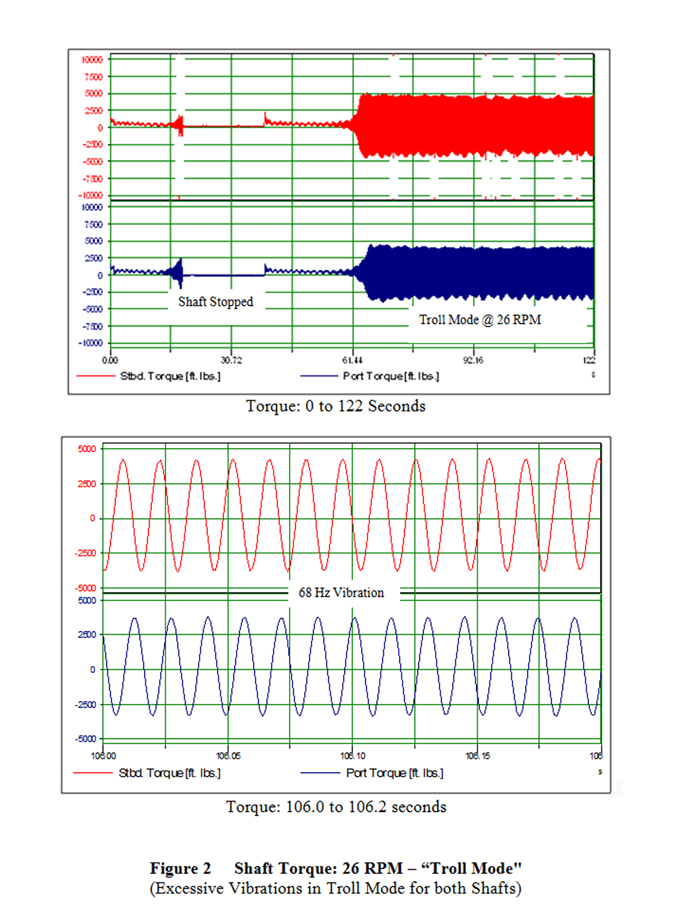

The primary objective of this project was to measure and report on the powering performance and shafting torsional vibration characteristics during sea trials. The results of the measurements indicated that a speed of 12.9 knots was achieved with a total shaft power of 928 HP at a shaft speed of about 296 RPM. About 15% more power was developed with the new propeller at the same shaft speed. Excessive torsional vibrations were measured at low shaft speeds, resulting in gear tooth backlash. The minimum shaft speed was set to 60 RPM based upon the torsional vibration measurements. Figures 1 and 2 illustrate results of the measurements.

For this marine propulsion system, the TorqueTrak 10K telemetry instrument was used to verify and demonstrate the associated benefits of a recent system upgrade, namely, an increase in vessel speed at less power and less fuel usage. That is exactly what the designers had hoped to see. At the same time, the TorqueTrak 10K was used to check torsional vibration in order to put corrective measures in place.