Ariel Corporation was working on an issue with Rotor Bearing Technology & Software, Inc. (RBTS) for a company in Australia. Since its start up, the customer had experienced multiple elastomeric element failures in the drive coupling on their large coal bed methane booster compressor at loads and speeds in the design operating range. This compressor unit is driven by a natural gas engine.

The analytical torsional model initially predicted the first mode torsional natural frequency (TNF) to be below 800 RPMs (720 RPM at 30°C and 620 at 100° element temperature at rated engine torque).

Ariel’s Tom Stephens performed site testing with two TorqueTrak instruments with Micro-Measurements strain gages simultaneously: one for coupling dynamic torque, and one for coupling element temperature. Because these elements are part of the rotating coupling assembly, Ariel decided to use telemetry to transmit the signal from their internal temperature sensor. The measurement data indicated the coupling was acting much stiffer than originally modeled with the fundamental twist critical speeds between 800 – 850 RPM. Operating at, or even near, the critical speed was causing the coupling’s elastomeric elements to heat up. The drive train’s fundamental twist mode of vibration was being excited by the inherent unsteady torque demand from the compressor which resulted in damaging levels of torsional vibration in the drive coupling.

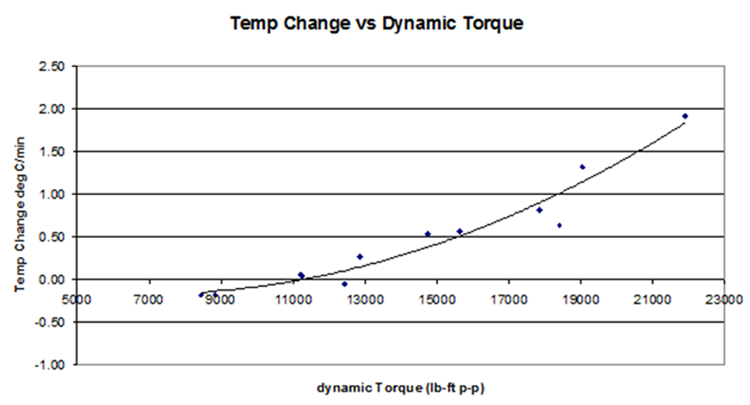

The plot shows the coupling element heat generation under different vibratory torque levels – a value below zero indicates that the coupling is cooling down and above zero indicates that it is heating up. Referring to this chart, to prevent the elastomeric elements from overheating, one can see that the vibratory torque level must remain below about 11,000 ft-lbs P-P.

Armed with this data, a slight modification was made to the setup of the coupling assembly which resulted in lowering the drive train’s fundamental twist frequency and ultimately improved compressor reliability. Binsfeld’s TorqueTrak products provided the required telemetry solution to facilitate the simultaneous monitoring both torque and temperature on a rotating coupling assembly which were essential to enabling Ariel and RBTS to fully understand the problem and arrive at a solution.