CENTA Transmissions Far East Pte. Ltd. used the TorqueTrak 10K telemetry instruments from Binsfeld Engineering to diagnose and solve a problem aboard a twin-propeller ship, where the couplings on both shafts repeatedly suffered damage after only a couple hours of sea trials. The coupling elements were replaced with new parts, but the same damage would quickly reoccur. Shaft alignment was checked by shipyard technicians, but no problem was found.

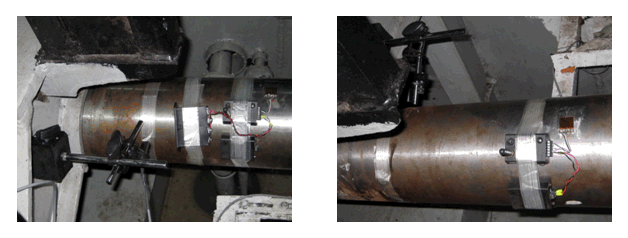

The Torsional Vibration Calculation (TVC) showed no abnormalities, but obviously something was not right. A deeper investigation was required. Two TorqueTrak 10K instruments were installed, one on each propeller shaft and the true dynamic torque on the shafts was measured.

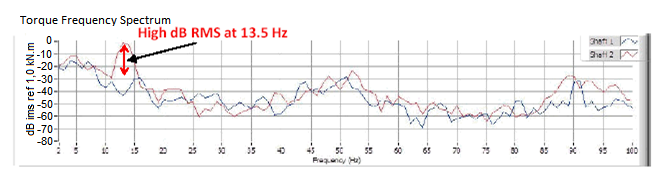

Testing revealed the presence of significant oscillating torque (torsional vibration) when the Controllable Pitch Propeller (CPP) was at 50 to 60 percent. The torsional vibration was significant enough to cause the coupling damage.

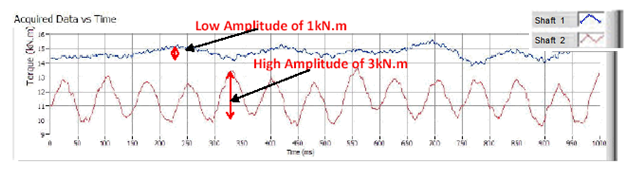

Another TVC was performed using a coupling with different shore hardness. The starboard side coupling was replaced with a 50SH element while keeping the port side as it was originally. New measurements were made with the TorqueTrak 10K instruments. This time the report showed a surprising difference.

For the starboard shaft the high vibratory torque that was previously present no longer existed. The higher shore hardness made a big difference. Both coupling elements were replaced with new ones rated at higher shore hardness, 60SH. This greatly reduced the torsional vibration strain and eliminated the breakage of couplings.