Torque is an important variable to the designers and manufacturers of wind turbine technology. Torque data is especially critical in the evaluation of wind turbine components such as bearings, gears, and braking systems. By providing the true mechanical work being generated by the rotor shaft, torque can be used to determine the true efficiency of the system: mechanical energy in – versus electrical energy out.

In order to collect torque data, a bondable strain gage sensor is applied to the shaft. The strain gage is a Wheatstone bridge circuit that changes resistance in response to distortion of the shaft surface when rotated under load. The relationship between this distortion (strain) and the mechanical work being generated (torque) is linear in the elastic region and based on the physical properties of the shaft. The best way to collect strain data from a rotating shaft is via a telemetry system that reads the analog signal from the strain gage and transmits it as a digital signal to a stationary receiver where it is collected for analysis or used for real-time process control.

The TorqueTrak Revolution system manufactured by Binsfeld Engineering Inc. provides torque, power (hp or kW), rpm and direction of rotation data continuously using inductive power and data transfer. It has been used successfully in many applications in the wind industry, where the typical service life goal for wind turbines is 20 years and meaningful validation trials may last on the order of months or years.

DESIGN VALIDATION

One of our clients tested a scaled-up design of their patented vertical wind turbine for 18 months. The 25-100 kW turbines being evaluated featured unique stationary stators that funneled and accelerated the wind into the rotor blades. “The robust and unique combination of the stator and rotor design allows the turbine to operate in Class 6 and 7 wind speeds (25-30 m/s). Most turbines cut out at 25 m/s,” they said. Our client added that they’ve been using the TorqueTrak Revolution to capture torque data for a publishable power curve. The data will validate the full-size models developed from 1/12-scale wind tunnel prototypes. They also plan to use the results to scale up designs in the 0.25-1 MW range and scale down designs in the 1-5 kW range.

TMA 25 KW VERTICAL WIND TURBINE

The National Renewable Energy Laboratory has also specified the TorqueTrak Revolution as one of over 150 sensors being leveraged to characterize all dynamic motions and loadings on a generic gearbox typically employed in most large-scale turbine designs. The goal of this collaborative effort between the Department of Energy, wind turbine OEM’s, drivetrain component and lubrication suppliers, and turbine owners and operators is the development of a complete mathematical model of the entire system, available in the public domain for the validation of improved gearbox designs.1

Two gearboxes in the 600-750 kW range are being built and instrumented for the investigation. One will be run on a 2.5 MW dynamometer at the National Wind Technology Center and the other will operate in the field on a turbine in the Ponnequin wind farm, both located in Colorado. The TorqueTrak Revolutionallows studying of torque loads when braking on high speed shafts. Occasionally – our customers find that generators may carry torque for a short period of time.

TEST STANDS

Ensuring quality and reliability is the reason another client in Iowa invested in two test stands for the gearboxes that represent the core of their powertrain. Their 2.5 MW wind turbine splits the torque from the rotor shaft through a multipath, load-distributing design to drive four generators, reducing component failures and extending the operating life.2

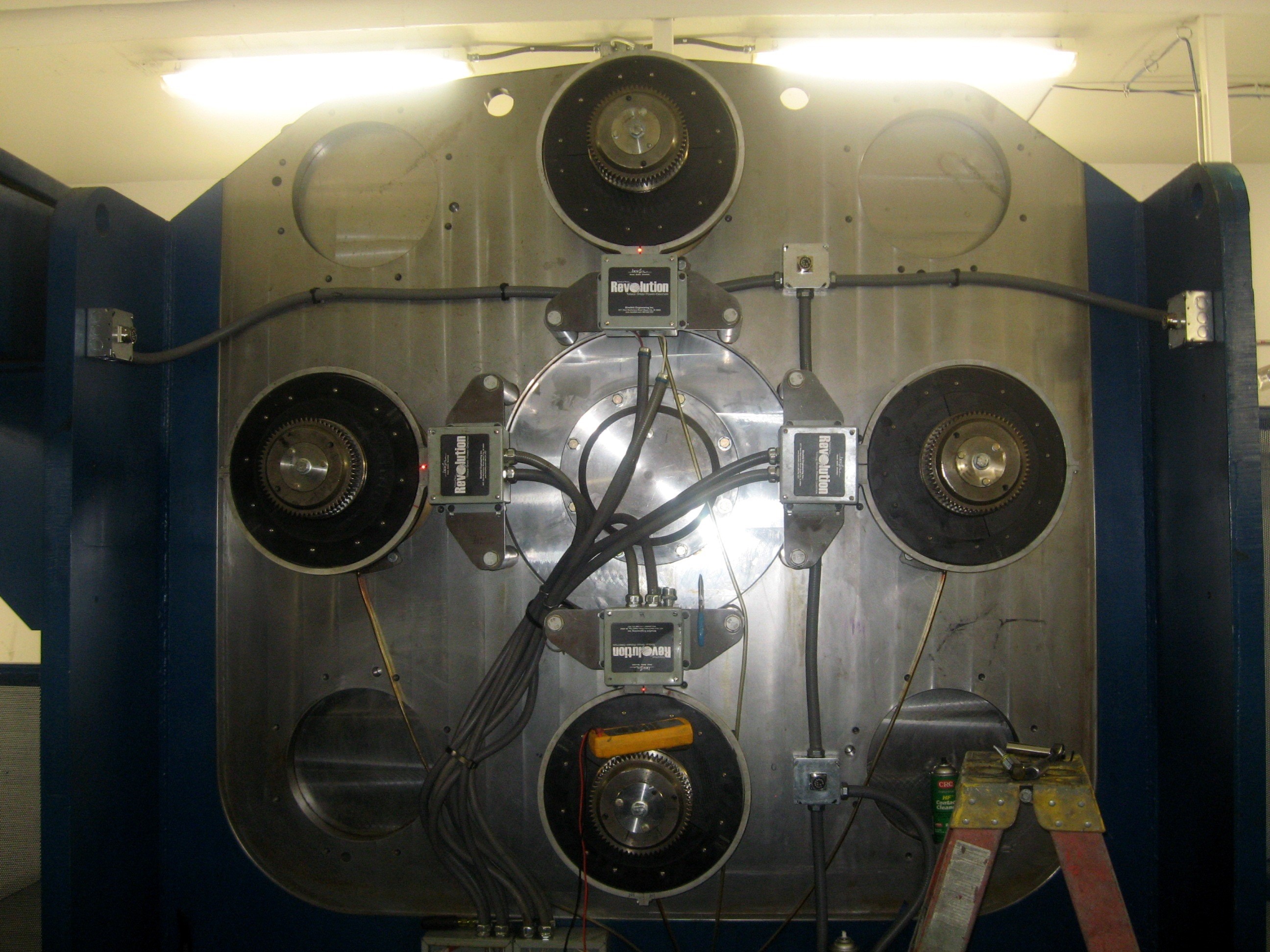

TORQUETRAK REVOLUTION SYSTEMS ON GEARBOX TEST STAND

To test production gearboxes, they built two test stands incorporating the TorqueTrak Revolution, one system monitoring torque on each of the four output shafts. The torque signals are fed back to a PLC that controls a hydraulic servo loop regulating rotary actuators that maintain the desired torque load on each shaft. Both regular production and endurance testing have been performed on the test stands. The endurance tests simulated 20 years of operation in 1,100 hours. This method was used because continuous torque data was necessary.

CONDITION-BASED MONITORING

Utilizing torque as part of a condition-based monitoring (CBM) strategy is not currently standard practice in the wind industry. Bearing temperatures, vibration, and oil particulates are commonly measured variables relied upon to monitor drivetrain health. Measuring, and logging, torque data is important to many components – especially at it relates to the gearboxes.

SUMMARY

The measurement of true mechanical torque is a key parameter for the wind industry in test stand and design validation applications. It may hold promise as a worthy drivetrain CBM variable in the future. As the examples show, the TorqueTrak Revolution system is an ideal instrument for the continuous measurement of torque in these cases.

THE TORQUETRAK REVOLUTION SYSTEM

The TorqueTrak Revolution delivers continuous torque and power data using inductive, noncontact technology, resulting in long-term, reliable operation. Installation is simple; shaft modification and machine disassembly are not required. It features sophisticated 14-bit signal processing for a precise output signals and many setup tools for easy calibration and scaling.

References:

• W. Musial, S. Butterfield & B. McNiff (2007). Improving Wind Turbine Gearbox Reliability. Presented at the 2007 European Wind Energy Conference, paper preprint, NREL/CP-500-41548: http://www.nrel.gov/docs/fy07osti/41548.pdf

• Clipper Windpower Plc (2006). Liberty.