What is torque telemetry?

Torque telemetry is a wireless method of measuring torque on a rotating shaft. At its most fundamental level, a torque telemetry system’s “job” is to energize, transmit, and process the data received from a sensor (such as a strain gage, usually bonded to the shaft) and output the torque data in a usable format for analysis. Wireless transmission of the data can happen using one of two types of telemetry: Radio Frequency or Induction. Inductive telemetry systems transfer the torque signal via an inductive link between a rotating coil and stationary coil. Radio Frequency (RF) telemetry systems use high-frequency radio waves (not much different than an FM car radio) to transmit the torque signal off the shaft to a nearby receiver.

Which system to use is application-dependent. Inductive telemetry systems are ideal where long-term testing is needed on a particular shaft while battery-powered RF systems are best suited for short-term diagnostic tests on a variety of different shafts.

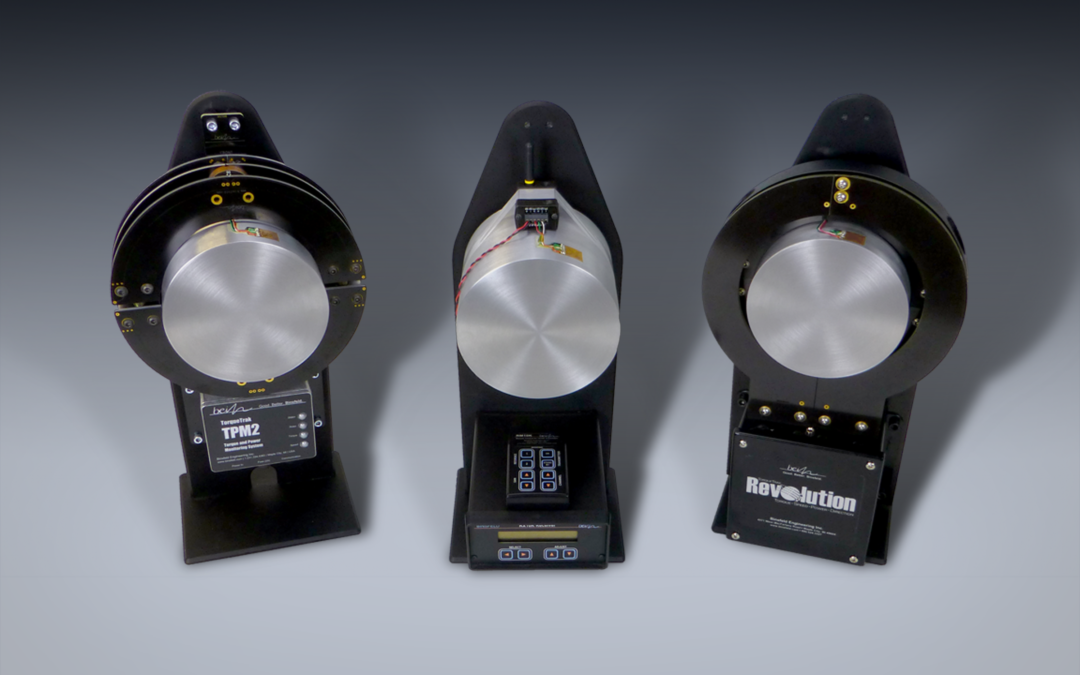

Figure 1. An RF torque telemetry system (left) transmits the signal from the antenna to a nearby receiver. An inductive torque telemetry system (right) transmits the signal via an inductive link between a rotating collar and stationary collar.

How does a torque telemetry system work?

All torque telemetry systems require that a sensor such as a strain gage be bonded to the shaft. Once the gage is bonded to the shaft, it is then connected to the torque telemetry system. To understand how a typical torque telemetry system works, it is useful to follow the flow of the signal through the system:

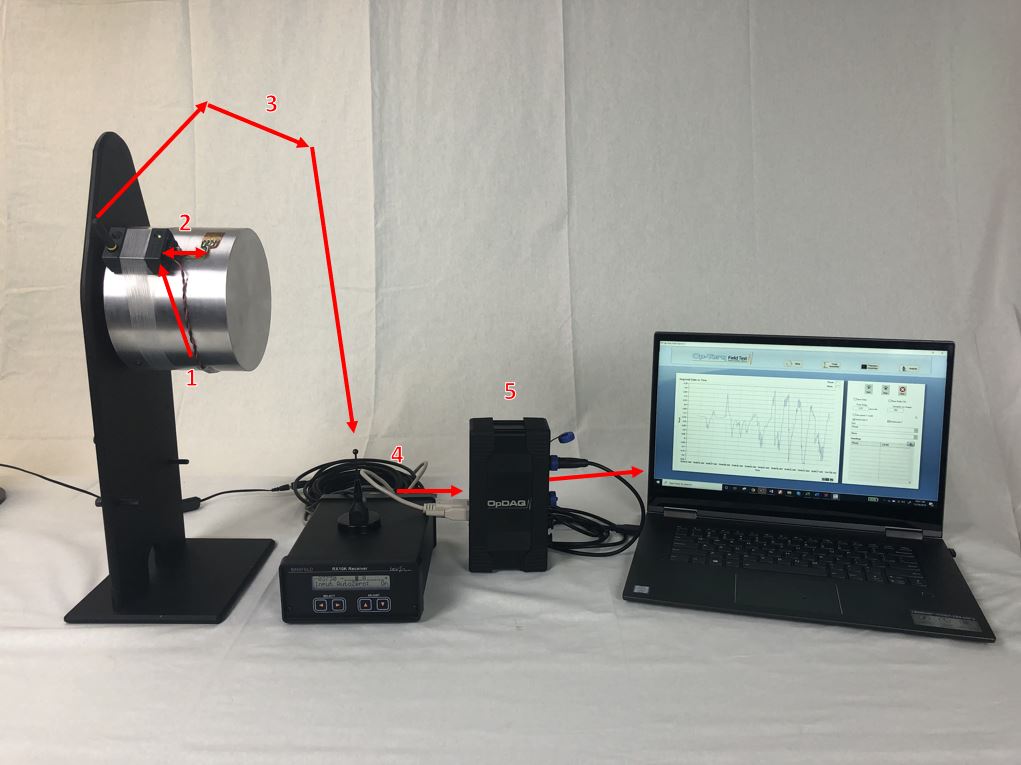

Figure 2. The signal path for an RF torque telemetry system.

1. Transmitter is energized via Battery or Induction

2. Strain gage converts twist of the shaft to an electrical signal

3. Electrical “torque” signal is transferred from the shaft wirelessly using telemetry

4. Signal is received, processed and output by the receiver

5. Signal is converted to torque value and recorded to a data acquisition system

Torque telemetry systems have significant benefits in the world of rotary torque measurement. They are highly accurate, provide a clean noise-free signal, are easy to install, and don’t require shaft modification. These benefits make torque telemetry systems ideal for a wide variety of applications in Marine, Manufacturing, Mining, and Energy industries. At Binsfeld, we have been designing torque telemetry systems for over 40 years. Contact us today to discuss your application. We are here to help!