MINING

TORQUE AND POWER MONITORING

MINING OVERVIEW

With the enormous cost of downtime in mining operations, Binsfeld understands how important it is for companies in the mining industry to keep their operation running efficiently. TorqueTrak products are used in the development, commissioning, and operation stages of a variety of mining equipment including conveyors, excavators, and mills. Our products allow clients in the mining market to measure the true mechanical torque and power on virtually any rotating shaft, helping minimize downtime and increase operational efficiency.

Diagnostics/Testing

- Root cause pulley and bearing failures

Process Monitoring & Control

- Reduce downtime by knowing when coupling, gearbox, or bearing performance is degrading

- Initiate preventative maintenance or replace worn components only when needed

Performance Validation

- Verify actual conveyor performance against theoretical models (demand power, shaft torque, dynamic behavior)

- Confirm adequate load sharing and VFD functionality

Process Improvement

- Increase conveyor capacity by knowing power losses in gears/coupling

MINING CLIENTS

KOMATSU

CAT

AC-TEK

VOLVO

KVÆRNER

MINING PRODUCTS & SERVICES

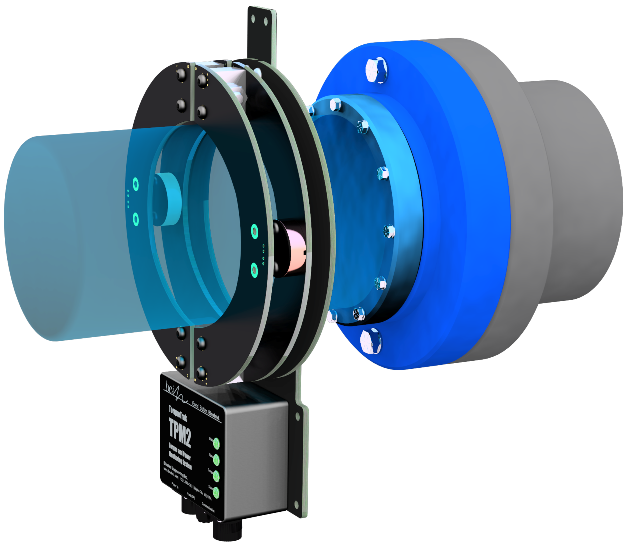

TORQUETRAK TPM2

Sealed torque and power monitoring system with digital data output.

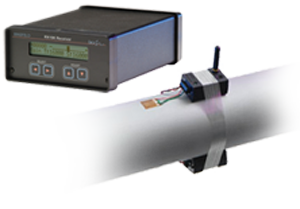

TORQUETRAK 10K

Temporary torque measurement system for rotating shafts.

TORQUE MEASUREMENT SERVICES

When you need to know the real torque (or horsepower) on your machinery or drive system consider Binsfeld Torque Measurement Services.

MINING CASE STUDIES

Troubleshooting Overland Conveyor VFD

The following application story is taken from the “THE VALUE OF FIELD MEASUREMENTS ON OVERLAND CONVEYORS” by David J. Kruse and Ryan Lemmon of Advanced Conveyor Technologies (AC-Tek). The TorqueTrak 10K temporary torque measurement system was used to provide the...