TORQUETRAK SPM-ION

TORQUE & POWER MONITORING SYSTEM

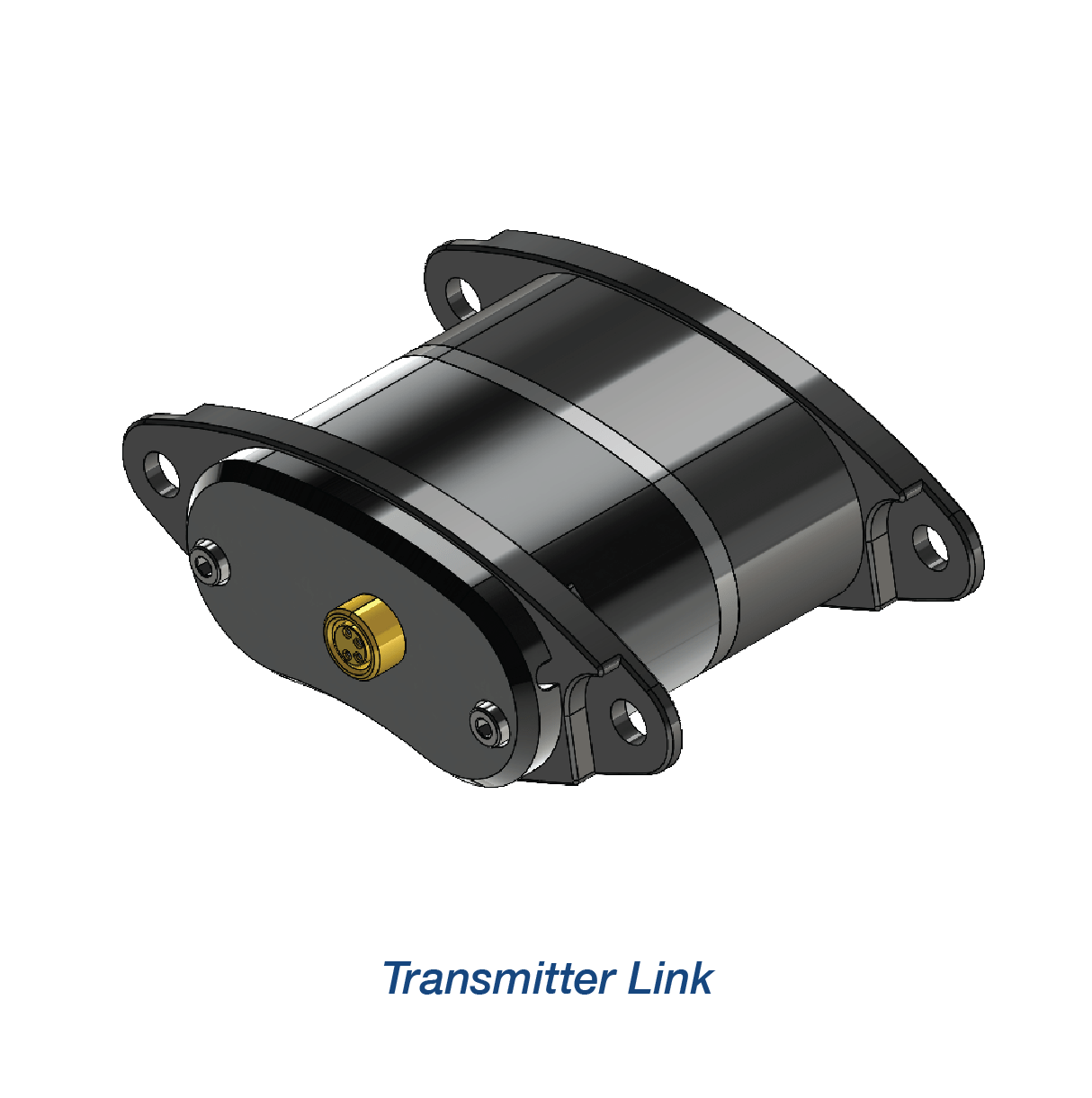

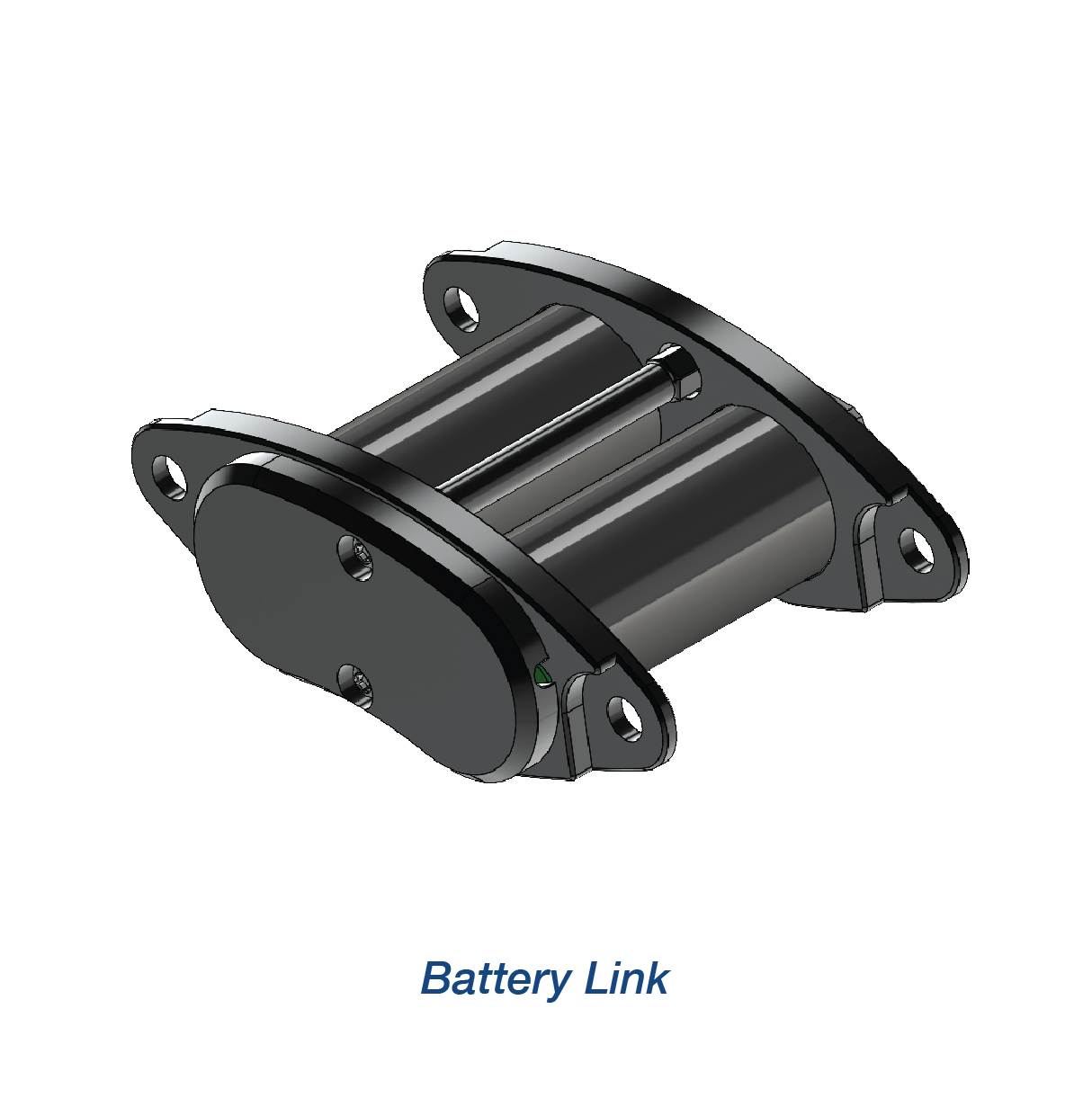

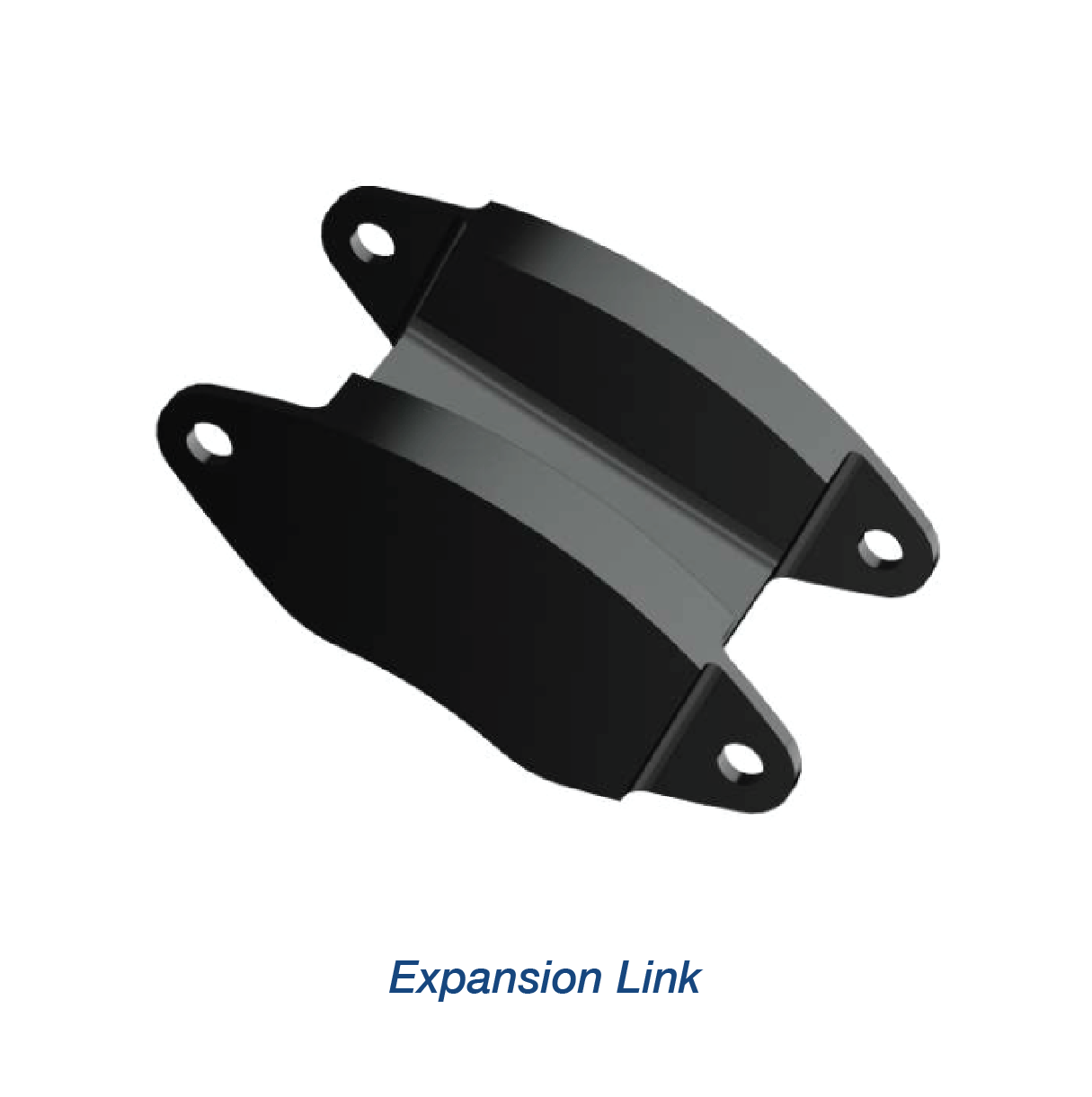

The TorqueTrak SPM-iON is a state-of-the-art strain gage-based solution designed to provide torque, RPM, and power measurements on rotating shafts, without the need for shaft disassembly or modification. The system only includes two primary components and does not require a base mount. The innovative chain link design allows for fast lead times, simplified installation, and easy interchangeability between shaft sizes. Electronics are encased in potting and protected by a strong metallic housing, ensuring reliable long-term operation in the most abusive environments.

Suggested Uses

Continuous monitoring on larger shafts. Measures torque, RPM, and power.

Features & Benefits

Modular – The chain link design of the collar allows for easy change between shaft diameters. Chain links are quickly added or removed using standard hardware.

Fast Lead Times – Due to the chain link design of the collar, parts are stocked and ready to ship. No time-extensive machining required.

No Base Mount Required – The stand-alone shaft “clamp-on” collar assembly requires no base mount. This eliminates the need for custom mounting brackets or on-site welding. Installation is dramatically simplified.

High Accuracy – The use of a strain gage sensor and a 24-bit ADC ensure the most accurate measurements possible.

Built-In Gyro – Shaft speed is measured with internal gyro, eliminating need for more cable runs. Power is automatically calculated from torque and speed measurements.

Low Maintenance – Highly optimized electronics ensure minimal electricity consumption for the transmitter, with battery autonomy of two years. Sleep mode is also available when the shaft is not turning, extending the battery life even longer. Battery replacements take minutes.

SPM-iON Shaft Collar Transmitter

|

Electrical Consumption: |

<1mA @ 3.6 V |

|

Batteries: |

3.6V LiSoCl2 (lowest self-discharge) |

|

Strain Gage Sensor: |

350 Ω torque pattern, welded or bonded |

|

Autonomy: |

2 years on 10x 3.6AH, 3.6V batteries |

|

ADC Resolution: |

24 bits |

|

Torque Accuracy: |

± 0.1% |

|

RPM Accuracy: |

± 1% |

|

Maximum RPM: |

3000 rpm |

|

Protection Rating: |

IP 65 |

|

Minimum Shaft Diameter: |

64 mm (2.5 in) |

|

Signal Transmission: |

Up to 20m (65 ft) line of sight |

SPM-iON Receiver

|

Supply Voltage: |

9-36 VDC |

|

Current Consumption: |

40mA max |

|

Electrical Isolation: |

500V |

|

Storage Temperature: |

-40°C to 85°C (-40°F to 185°F) |

|

Operating Temperature: |

-40°C to 85°C (-40°Fto 185°F) |

|

Humidity: |

10% to 90% non-condensing |

|

Vibration: |

5 – 50 Hz @ 20 mm/s ±1.0g max |

|

Conformity: |

CE Compliant |

|

Degree of Protection: |

IP 65 |

|

Sampling Rate: |

4 samples per second |

|

Protocol: |

Modbus RTU over RS485 |

DOCUMENTATION

TT SPM-iON User Guide [PDF]

TT SPM-iON Datasheet [PDF]

TORQUE CALCULATORS

MARKETS

Marine >

Mining >

Industrial & Manufacturing >

Energy >

Agricultural >

Civil Engineering >

BINSFELD ENGINEERING INC.

4571 W. MacFarlane Rd.

Maple City, MI 49664 USA

TORQUETRAK

Binsfeld’s Torque Measurement Systems measure true mechanical torque and power on rotating shafts. We also offer consultation, strain gaging and installation services.

TEMPTRAK

Binsfeld’s Rotary Temperature Transmitter Systems provide accurate and reliable temperature control on heated godets and calendars. We also offer design and OEM services.

STAY UP TO DATE

Follow us on LinkedIn for featured application stories, relevant news, tips, and new product release information for our torque measurement products.